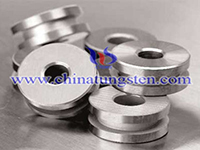

Applications of Tungsten Carbide Pellet

Tungsten carbide pellet is widely used in manufacturing industry, engineering machinery, metallurgical and mining industry. By piling welded, spraying welded to the surface of tools or working parts to form a hardened wear-resistant layer, it can greatly improve the working life of the tools.

Tungsten carbide pellet is commonly used in applications requiring extreme hardness, excellent wear resistance, and ability to withstand impact and shock. Applications for carbide pellets include but are not limited to:

Shotgun shell

Pelletizing machines or pelletizers.

Hardbanding new and used drill pipe collars

Buildup of oil field drill bits

Welded in steel substrate in various wear resistant applications

Tungsten carbide pellets are for extreme wear applications. Tungsten carbide pellets are incorporated into the plate in high wear areas. The tungsten carbide pellet resists wear and impact, imparting toughness and protection into the steel substrate, increasing part-life, reducing change-out time and protecting valuable equipment.

Tungsten carbide pellet is also found inside a shotgun shell. Lead shot and bullets have been banned in many areas because they poison the environment. The main substitute materials are steel, bismuth and tungsten. The main advantages of tungsten carbide pellet are that it's very dense, and very hard. The density allows the pellet to fly long distances without slowing down, while the hardness allows the tungsten carbide pellet to keep its shape while being accelerated by the powder charge, which increases the muzzle velocity. (When pellets of lead are deformed during acceleration, that deformation absorbs energy which could have gone into acceleration, and furthermore lead only has about half the density of tungsten.)

Drill bit is the cutting or boring element used in drilling oil and gas wells. Most bits used in rotary drilling are roller-cone bits. The bit consists of the cutting elements and the circulating element. For the cutting elements, tungsten carbide pellet is to build up the strength, hardness and wear resistance needed in the working of drilling .