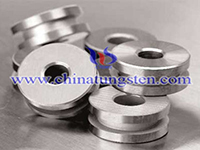

Tungsten Carbide Pellet

Tungsten carbide pellet is used to be welded onto the surface of the tools or work parts to form a hardened wear-resistant layer in order to provide protection against abrasive wear and therefore increase the service life of the tools and work parts. Pellets are small particles typically created by compressing an original material. It is cost effective and is widely used in the drilling and manufacturing industry, engineering machinery, metallurgical as well as mining industry etc.

Tungsten carbide pellet is unique because it is manufactured in a sintering process, whereupon the metal powder is formed under extreme heat and pressure. Tungsten carbide pellet is extremely hard. The manufacturing technique makes these pellets substantially more expensive than other materials, but practically inert. The relative inertness makes tungsten carbide pellet extremely resistant to interaction with various liquids and alloys.